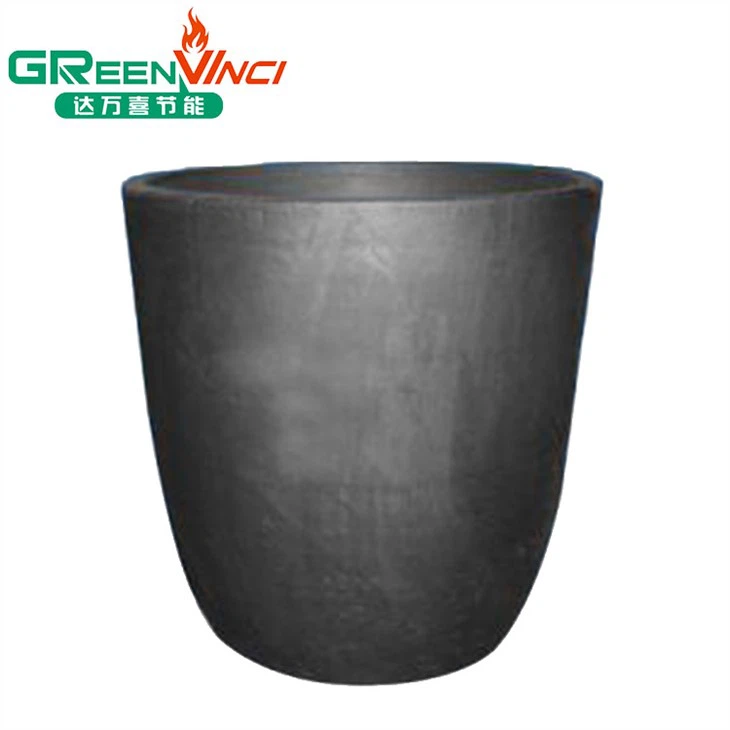

Product description

GreenVinci aluminum melting crucible is a kind of Silicon Carbide Graphite Crucible.

The crucible is mainly used for the melting of aluminum, aluminum alloy, zinc alloy and frying aluminum ash. Suitable crucible furnaces like biomass furnace, oil furnace, gas furnace, tilting furnace etc. The melting point of the metal is 620~920 °C.

Product characteristics

-The excellent low-temperature oxidation resistance makes the crucible have good thermal conductivity for a long time, and at the same time effectively prevents the strength of the crucible from decreasing due to oxidation.

-Special material design, with excellent crack resistance, to prevent cracks in use.

-The non iron material design can prevent the iron element from melting into the aluminum melt and polluting the aluminum melt.

Applicable metal melting point

620-920℃

Scope of application

Coke furnaces, gas furnaces, etc

Physical and chemical features:

1.High strength: select high quality material, high pressure pressing reasonable combination, good high temperature strength, scientific product modeling, high pressure bearing capacity.

2.High temperature resistance: use temperature 400-1700C, different range optional

3.Erosion resistance: advanced material formulations that effectively resist the physicochemical action of the melt

Physical date

1.Bulk density: 2.21-2.25g/cm3

2.Apparent Porosity: 9-12%

3.Modulus of Rupture: 8-12 Mpa

4.Thermal Expansion Coefficient: 3-4.5(10-6K-1)

Chemical Analysis

1. C (free C) : 37-42%

2. SiC(silicon carbide): 35-40%

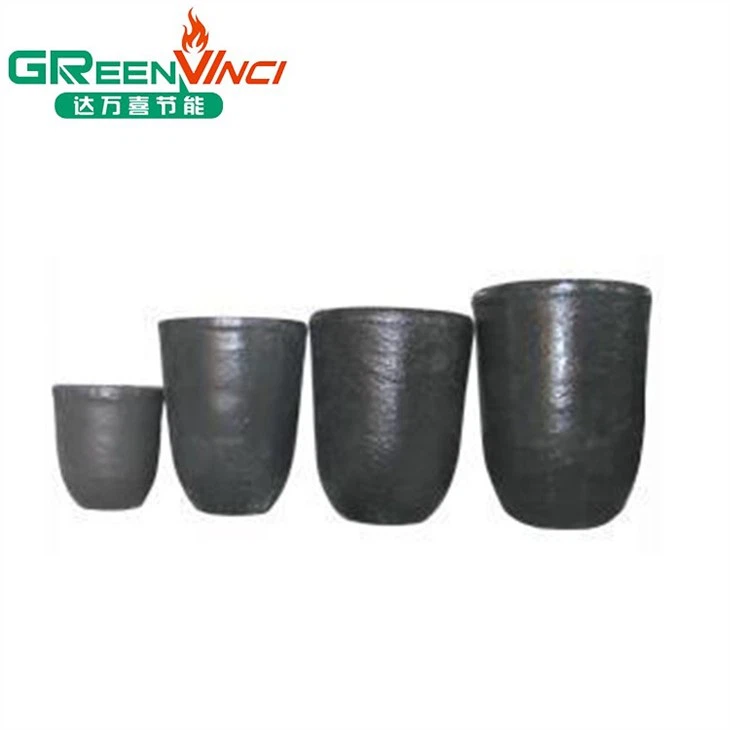

Product specifications

Item No. | Upper dia | Height | Inner dia | Bottom outer dia |

300 kg | 615 mm | 710 mm | 530 mm | 330 mm |

500 kg | 735 mm | 900 mm | 640 mm | 440 mm |

600 kg | 780 mm | 900 mm | 682 mm | 440 mm |

800 kg | 880 mm | 880 mm | 785 mm | 360 mm |

1000 kg | 1040 mm | 850 mm | 925 mm | 555 mm |

Product storage method

Do not touch water, easy to absorb moisture and need to be placed in a dry place

Product Maintenance

1. Preheating must strictly follow the operating guidelines;

2. The input method should be placed obliquely, not straight;

3. Before stopping the furnace, the aluminum alloy must be scooped clean. Otherwise, if you start the furnace again, the furnace will burst when it expands with heat and contracts with cold.

4. The slag on the crucible wall needs to be scraped off in time during the production process, because the slag also has an expansion coefficient and the crucible mouth is easy to crack

Product Warranty

Quality problems caused by non-human operations are covered by the warranty.

Problems caused by human operation are not covered by the warranty.

Packing and shipping

The aluminum melting crucible which simply called graphite crucible is packed in wooden case and fixed with safety stuff to ensure it can arrive at the customer's site without any damages.

GreenVinci Biomass Machinery Co., Ltd.

Foshan City, Guangdong Province, China

Hot Tags: aluminum melting crucible, manufacturers, suppliers, customized, automatic, environmental, non-pollution, cost saving, energy saving, high efficiency