Industrial Solid Waste Gasification Burner Description

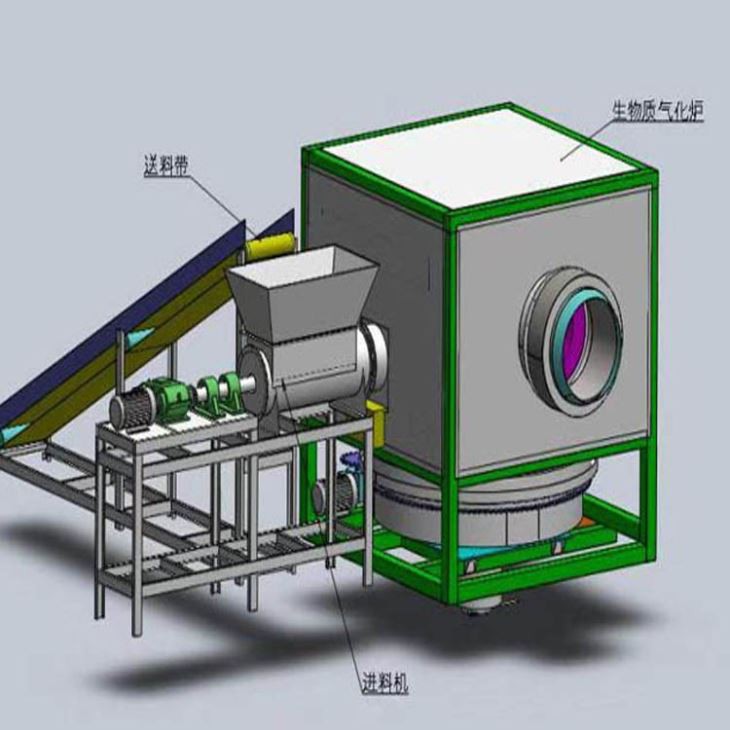

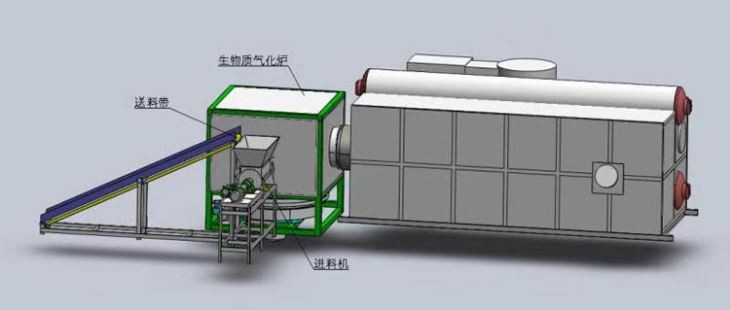

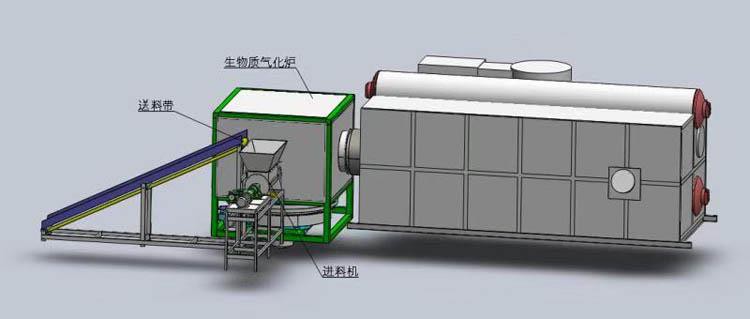

GreenVinci solid waste pyrolysis gasification burner system is a newly developed burner system with first pyrolysis and gasification chamber + surrounding air mixed combustion + second combustion chamber + full combustion treatment.

Compared with the traditional direct combustion technology, the first chamber adopts pyrolysis gasification technology.

The Industrial solid waste gasification burner can apply to the industrial boiler, dryer, kilns and melting furnace to provide heat energy to the production line.

Fuel: cloth waste, sponge, leather, paper waste, plastics, PP, BOPP etc.

Industrial Solid Waste Gasification Burner Features

Pyrolysis gasification burner can be divided into raw material layer, drying layer, pyrolysis layer, gasification layer, oxidation layer and ash slag layer from top to bottom;

♦ The first gasification chamber and second combustion chamber are adjacent so it is of better heat preservation and heat transfer, high efficiency, stable temperature that kept at 850 ~1150 ℃;

♦ The equipment occupies less space and saves investment.

♦ Full combustion of gas, high burnout rate, exhaust gas treatment meets EU standards or ultra-low emission standards, smoke-free chimneys can be achieved.

♦ High degree of automation, real-time display of pollutant indicators.

Compared with the traditional direct combustion burner, the pyrolysis gasification burner operates steadily with very little dust and has a unique automatic rotary grate, which has the functions of slag breaking, slagging prevention and better slag discharging and slag breaking.

1. When solid waste is pyrolyzed, gasified and burned under anoxic conditions, the amount of dust is small, which greatly reduces the workload of subsequent tail gas purification.

2. There are thermal decomposition and precise control in different stages in the burning process.The unique high-temperature combustion chamber (second combustion chamber) completes the high-temperature oxidation process without secondary harmful gas pollution, avoiding the generation of dioxin, so it can meet the specified flue gas standard;

3. Introduce German technology and adopt advanced grate technology to control slag discharging time. At the same time, it can play the role of slag discharging and slag breaking so as to avoid slagging phenomenon of incineration sinter block.

4. When the calorific value of solid waste is above 2200 calories, no additional fuel is needed for burning, and the temperature of the second combustion chamber is above 1000 ℃.

5. Combining with patented technology, the traditional 2 direct combustion chambers are transformed into pyrolysis gasification combustion chambers, which improves the burnout rate of ash and the burning efficiency of rotary kiln. It also has comprehensive functions such as slag discharging at room temperature, slag crushing, airtight and so on.

6. Low cost, short construction period, easy operation, small land occupation;

Industrial Solid Waste Gasification Burner Specifications

Customized capacity from 0.3 -30 ton, a few of models showed at the following list.

| Capacity | 300 kg | 500 kg | 750 kg | 1000 kg |

| Fuel | Wood chips, BOPP, cloth waste, leather, sponge and other combustible solid wastes | |||

| Temperature | 800~1200℃ | 800~1200℃ | 800~1200℃ | 800~1200℃ |

| Size | 2.6*2.6*3m | 3*3*3m | 5.2*2.6*3m | 6*3*3m |

| Number of rotating grate | 1 | 1 | 2 | 2 |

| Electric cabinet | All motors are equipped with frequency converter Converter brand: Delixi | |||

GreenVinci Introduction

GreenVinci Biomass Energy Co., Ltd. is a high-tech enterprise that specializes in energy, environmental protection, energy-saving technology development, product manufacturing and sales.

From 2009, we have been insisting to provide green solution for industrial heating system with a team of professionals in the field of boilers, drying, metal melting, biomass industry.

We are a China leading manufacturer of solid waste gasification burner, briquette machine, pellet making machine, pellet burner, biomass gasifier, hot air generator, hot water boiler and aluminum melting furnace. Our products are exported to many countries such as Malaysia, Thailand, Indonesia, Vietnam, India... with good reputation.

In the next three years, we will become the largest exporter of biomass equipment in South China.

Pre and after sales service for the solid waste burner

Pre-sales service

Factory and running sites visiting! The customer can come to our factory to check and see the machine operating site near our factory.

Life-long online support and low-cost maintenance!

FAQ of Industrial Solid Waste Gasification Burner

(1) Is this process is pyrolysis or Incineration?

The solid waste pyrolysis gasification system adopts the advanced primary pyrolysis gasification + surrounding wind combustion. The high-temperature combustible gas produced by waste material pyrolysis at high temperature is fully combusted by secondary air supply system.

(2) Is flue gas treatment is required?

If required please described the process. The corresponding bag type dust collector is equipped to remove the dust particles in the exhaust gas.

(3) What's the required moisture of the fuel?

≤30%

(4)What's the required size of the fuel?

The wood chips can be 200 mm long and 50 mm wide, and the plastic film can be used after crushing.

Hot Tags: industrial solid waste gasification burner, manufacturers, suppliers, customized, automatic, environmental, non-pollution, cost saving, energy saving, high efficiency